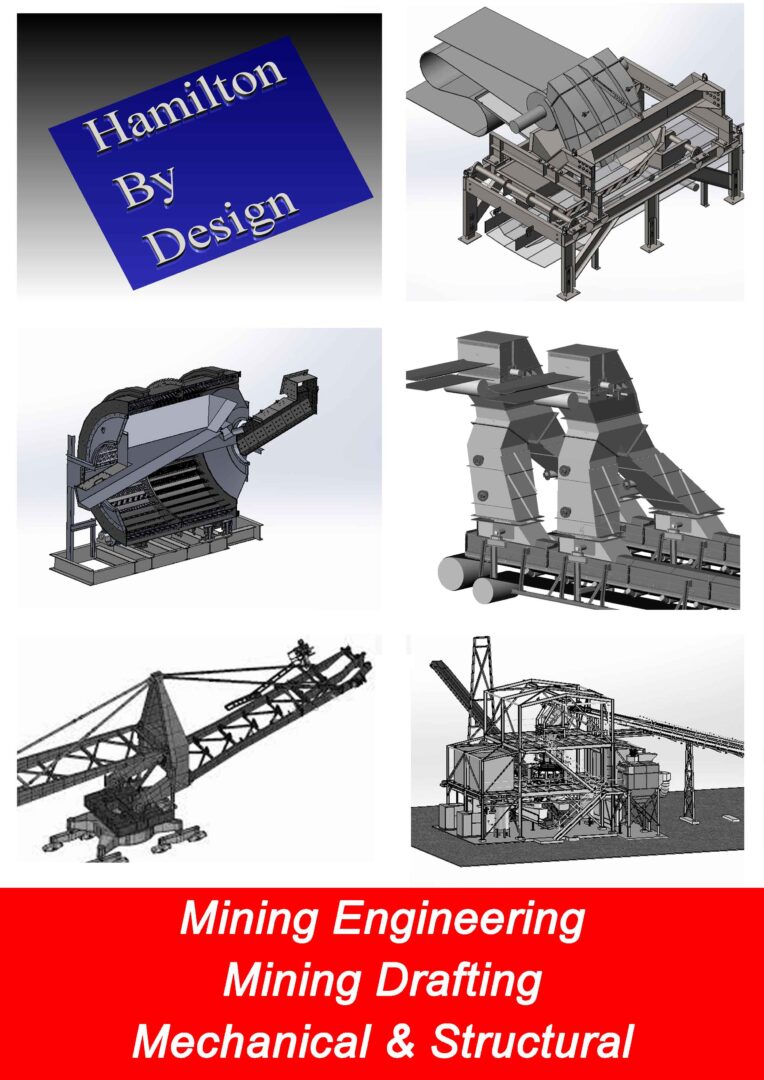

Engineering Hoppers, Chutes & Transfer Stations with Precision 3D Scanning

In mineral processing operations, hoppers, chutes, rock boxes and transfer station feeders operate under constant impact, abrasion and high material loads. Poor geometry, misalignment or undocumented modifications can lead to excessive wear, blockages and unplanned shutdowns.

At Hamilton By Design, we integrate engineering-led 3D laser and LiDAR scanning into hopper and chute design workflows — ensuring modifications and upgrades are built on verified site conditions.

Why Scan Before Designing or Modifying Chutes?

Mineral processing infrastructure often evolves over time:

Chute liners replaced

Rock boxes modified

Feeders upgraded

Structural supports altered

Transfer points adjusted

Relying on legacy drawings can introduce risk. 3D scanning captures actual geometry before design begins.

This reduces:

✔ Material build-up issues

✔ Misaligned transfer points

✔ Structural interference

✔ Premature liner wear

✔ Fabrication errors

3D Scanning for Mining & Mineral Processing – Orange NSW

For mining and mineral processing projects in Orange and regional NSW, we provide engineering-grade 3D scanning to support chute redesign, wear analysis and structural upgrades.

Learn more about our scanning capability in Orange:

👉 https://www.hamiltonbydesign.com.au/3d-scanning-engineering-in-orange/

LiDAR Scanning Solutions Across Australia

Large mineral processing plants require efficient capture of conveyors, transfer stations, bins and supporting structures.

Our LiDAR scanning solutions provide:

Rapid plant-wide geometry capture

Structural steel verification

Conveyor alignment assessment

Accurate base data for modelling

Engineering-ready point clouds

Explore our LiDAR scanning capability:

👉 https://www.hamiltonbydesign.com.au/3d-lidar-scanning-solutions-australia/

3D Laser Scanning Across Australia

Hamilton By Design supports mining operations nationwide with structured scanning workflows designed for engineering outcomes.

Our laser scanning capability supports:

Chute redesign and optimisation

Rock box modification

Transfer station upgrades

Feeder alignment verification

Shutdown planning

Structural strengthening

Discover our national scanning services:

From Scan to Chute Engineering

Our process integrates:

3D site capture → Point cloud verification → CAD modelling → Flow assessment → Fabrication-ready documentation

This allows:

Improved material flow geometry

Better wear liner positioning

Reduced maintenance downtime

Enhanced safety compliance

Optimised bulk material handling performance

Engineering Confidence in Mineral Processing

Hoppers, chutes and transfer stations are high-wear, high-risk areas of mineral processing plants. Engineering decisions must be based on real geometry — not assumptions.

By combining precision scanning with engineering design, Hamilton By Design delivers practical, site-ready solutions for heavy industry.

If your operation requires hopper, chute or transfer station upgrades supported by accurate 3D scanning, we are ready to assist.