In industrial and mining operations, material handling systems — especially conveyors, hoppers, chutes, and transfer stations — are central to productivity. These components not only move material but also determine reliability, safety, and the cost of maintenance and downtime.

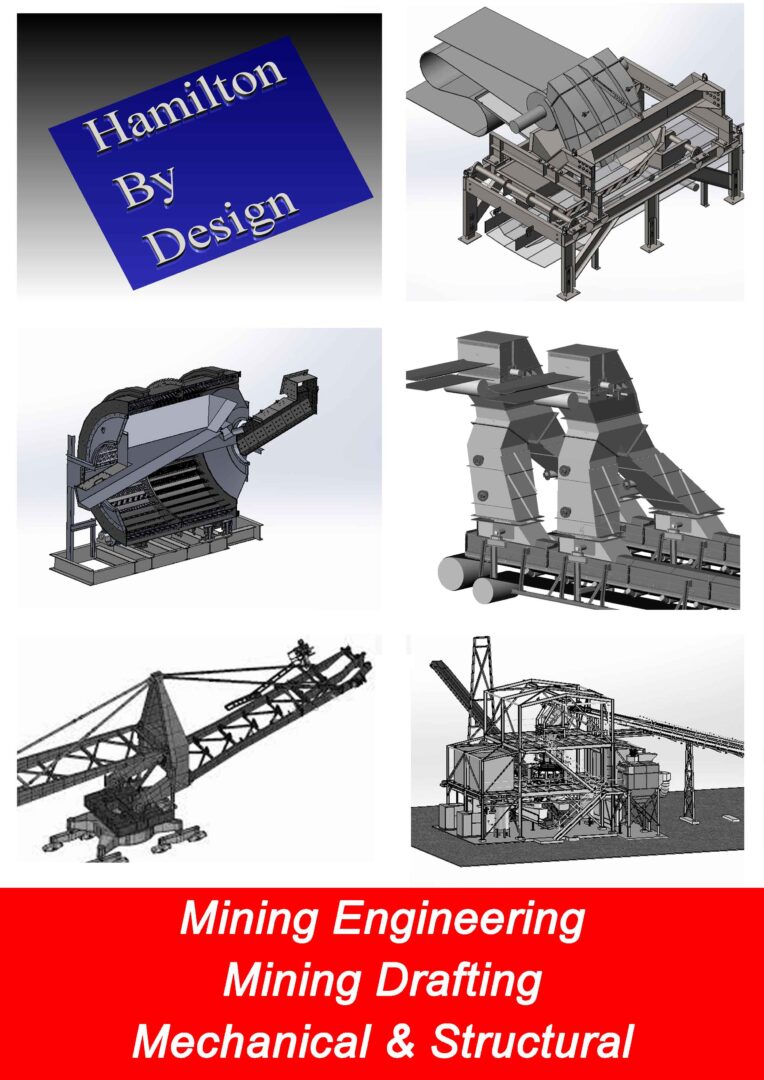

For businesses tackling these challenges, Hamilton By Design delivers engineering-led solutions that combine practical experience, cutting-edge tools like 3D scanning, and fabrication-ready design outcomes.

🔹 Smart Design for Complex Material Handling

Conveyors and transfer stations are often assumed to be simple. In reality, effective design requires deep understanding of mechanical loads, dynamic material flow, wear patterns, and site constraints. That’s why Hamilton By Design approaches bulk material handling as a complete engineered system — from hoppers and chutes all the way to conveyors and control points.

👉 Learn how the team supports conveyors, transfer points, ROM bins, hoppers and more with engineering-based design:

https://www.hamiltonbydesign.com.au/bulk-material-handling-mining-rom-conveyors/

🔹 Why Chute Design Matters (and How It Works)

Whether handling coal, hard rock or ROM material, chute and transfer designs are critical to keeping operations flowing. Poorly designed chutes can lead to blockages, excessive wear, and downtime — costing both safety and productivity.

Hamilton By Design’s approach blends accurate as-built data (often captured with 3D scanning) with advanced modelling and engineering judgement. This ensures that material flows smoothly, impact forces are controlled, and dust or spillage are minimised.

👉 Read more about chute design challenges and solutions here:

https://www.hamiltonbydesign.com.au/chute-design-for-mining/

🔹 Engineering Services for Tailored Solutions

Beyond individual components, Hamilton By Design offers full mechanical engineering services that include custom design and optimisation of conveyors, chutes, hoppers, and plant layouts. Their engineers integrate practical site insights with advanced tools such as CAD modelling, simulation, and design validation to produce solutions that fit first time in fabrication and installation.

👉 Explore the broader engineering capability supporting material handling systems:

https://www.hamiltonbydesign.com.au/home/engineering-across-australia/

Final Thoughts

Material handling issues are rarely isolated. They sit at the heart of plant performance — especially in mining, mineral processing, and heavy industry where throughput, wear, and reliability define profitability.

Hamilton By Design’s blend of engineering expertise, accurate data capture, and fit-for-purpose design ensures that conveyors, chutes, transfer stations, and hoppers don’t just work — they work right.

Whether you’re planning a new system or upgrading an existing one, the engineering insights and practical solutions offered here can make the difference between recurring headaches and a system that performs reliably day after day.